Top 10 Metal Cutting and Welding Innovations for 2024

Introduction to Metal Cutting and Welding Innovations

The world of metal cutting and welding is constantly evolving, with new technologies and innovations emerging each year. As we approach 2024, several groundbreaking advancements are set to revolutionize the industry, enhancing efficiency, precision, and safety. Below, we explore the top ten innovations that are poised to make a significant impact.

1. Laser-Based Cutting Technologies

Laser technology continues to lead the charge in cutting-edge innovations. In 2024, we expect further refinement in laser-based cutting tools that offer unparalleled precision and speed. These advancements reduce material waste and increase productivity, making them an invaluable asset in industrial applications.

Additionally, the integration of AI with laser cutting systems allows for real-time adjustments and optimizations, resulting in even greater efficiency. This combination is expected to become a staple in manufacturing environments worldwide.

High-Power Fiber Lasers

High-power fiber lasers are gaining momentum due to their ability to cut through thicker materials with ease. Their improved energy efficiency also reduces operational costs, making them an attractive option for businesses looking to improve their bottom line.

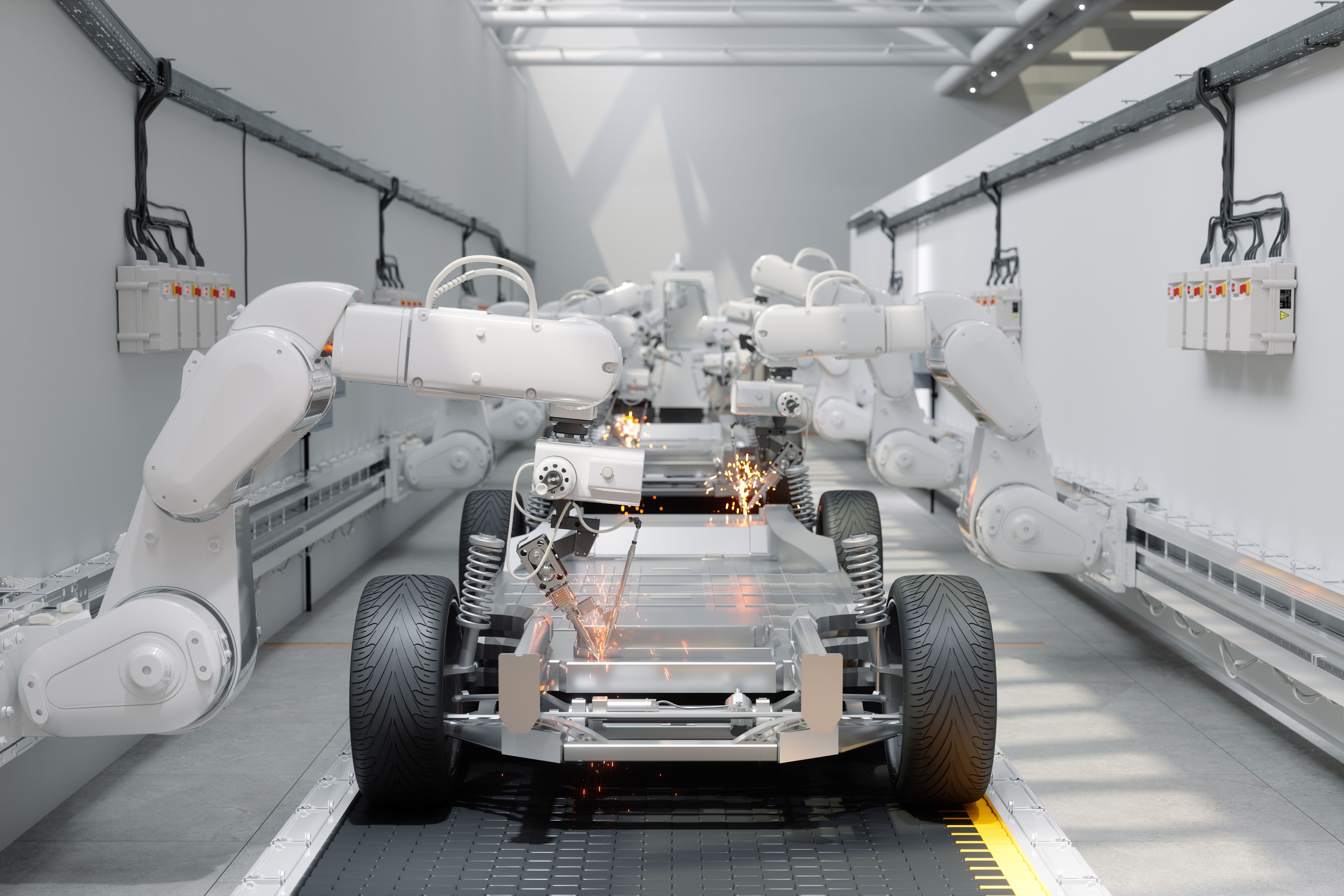

2. Advanced Welding Robotics

The use of robotics in welding has transformed the industry by offering enhanced precision and consistency. In 2024, expect to see even more sophisticated robotic systems that can handle complex welding tasks autonomously.

These systems are equipped with sensors and machine learning algorithms that allow them to adapt to different welding scenarios, ensuring high-quality results every time. This level of automation not only improves output but also enhances workplace safety by reducing human exposure to hazardous conditions.

Collaborative Welding Robots

Collaborative robots, or cobots, are designed to work alongside human operators. They are becoming increasingly prevalent in welding operations due to their flexibility and user-friendly interfaces. Cobots help streamline processes while allowing skilled welders to focus on more intricate tasks.

3. Hybrid Manufacturing Techniques

Hybrid manufacturing, which combines additive manufacturing (3D printing) with traditional metal cutting and welding techniques, is set to make waves in 2024. This approach allows for the creation of complex geometries that would be challenging or impossible with conventional methods alone.

By integrating these processes, manufacturers can achieve greater design flexibility and reduce lead times, ultimately accelerating product development cycles.

Benefits of Hybrid Manufacturing

- Enhanced design versatility

- Reduced material waste

- Shorter production timelines

- Cost-effective solutions for complex projects

4. Augmented Reality (AR) in Welding Training

Augmented reality is transforming welding training by providing immersive learning experiences that mimic real-world scenarios. AR technology allows trainees to practice welding in a virtual environment, reducing the need for expensive materials and equipment during the learning phase.

This innovative approach not only reduces training costs but also enhances skill acquisition by providing instant feedback and analytics on performance.

The Future of AR in Metalworking

The potential applications of AR extend beyond training. As the technology matures, it is expected to be integrated into day-to-day operations, assisting welders with precision alignment and real-time guidance during complex tasks.

Conclusion

The metal cutting and welding industry is on the brink of exciting developments as we enter 2024. From laser innovations to advanced robotics and hybrid techniques, these advancements promise to elevate the industry to new heights in efficiency and capability. Embracing these technologies will be crucial for companies looking to stay competitive and meet the evolving demands of the market.