Meet the Expert: Mr. Engineer Reza Mamaghani Rad on Magnetic Drills

RR

Introducing Reza Mamaghani Rad

When it comes to understanding the intricacies of magnetic drills, few are as knowledgeable as Mr. Engineer Reza Mamaghani Rad. With over two decades of experience in engineering and a specialization in drilling technology, Reza has become a trusted expert in the field. His insights have helped shape the design and functionality of modern magnetic drills, making them more efficient and user-friendly.

Reza's journey into the world of magnetic drills began during his early career as a mechanical engineer. His passion for precision tools and innovative solutions led him to explore the potential of magnetic drilling technology, where he has since made significant contributions.

The Importance of Magnetic Drills

Magnetic drills are essential tools in the construction and manufacturing industries. They offer precise drilling capabilities, especially on vertical and overhead surfaces where traditional drills may falter. What sets magnetic drills apart is their ability to adhere magnetically to metal surfaces, providing stability and accuracy.

According to Reza, the key advantages of using magnetic drills include enhanced safety, increased productivity, and superior accuracy. These benefits are crucial in industries where precision and efficiency are paramount.

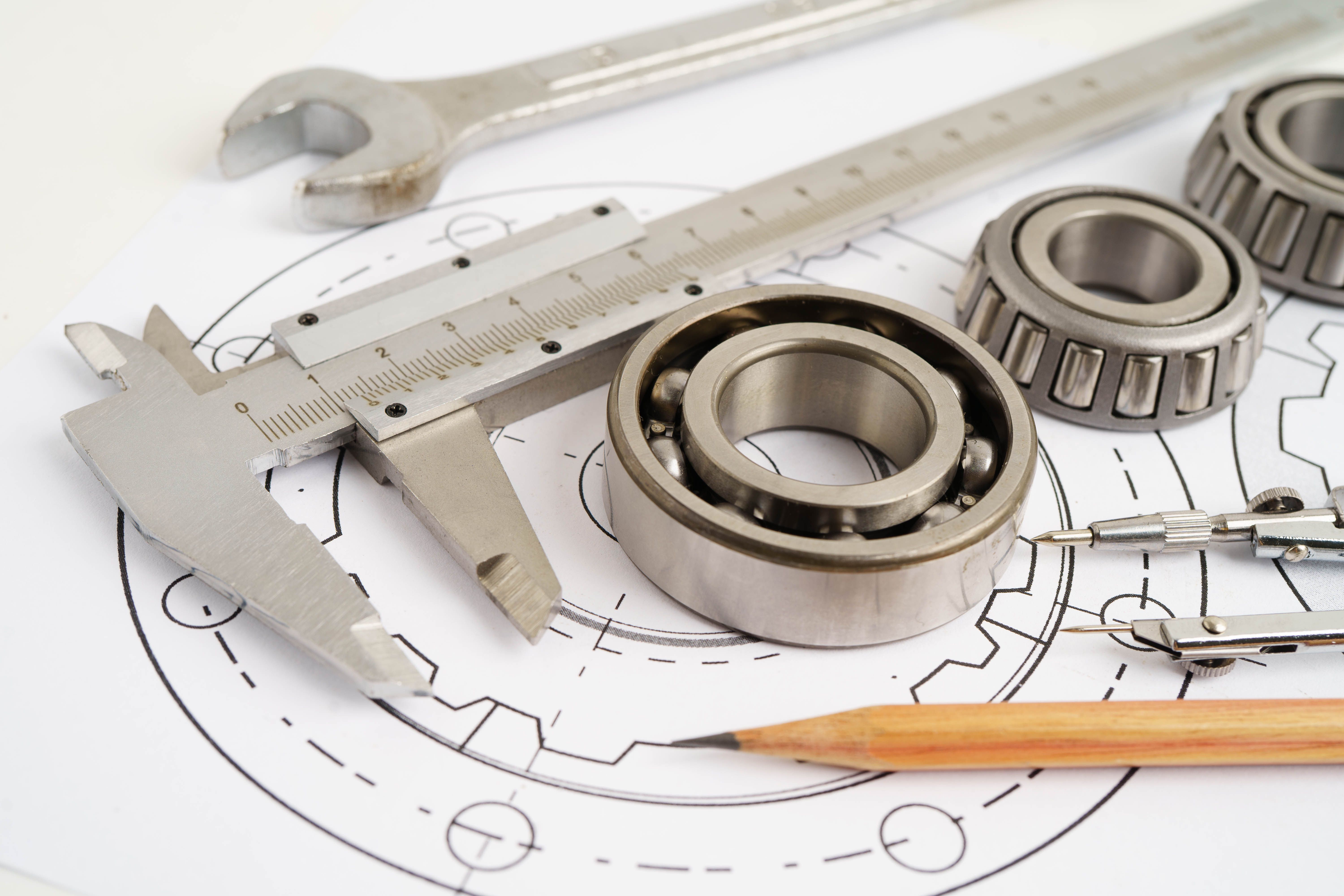

Understanding Magnetic Drill Components

A typical magnetic drill consists of several key components that work together to deliver exceptional performance. These include:

- Magnetic Base: Provides stability by adhering to metal surfaces.

- Motor: Powers the drill, available in various strengths depending on the application.

- Drill Chuck: Holds the drill bit securely in place during operation.

- Feed Handle: Allows the operator to control the drilling process with precision.

Reza emphasizes the importance of understanding these components to ensure optimal use and maintenance of magnetic drills.

Advancements in Magnetic Drill Technology

The field of magnetic drills is constantly evolving, with new technologies enhancing their capabilities. Reza has been at the forefront of these advancements, advocating for innovations like variable speed motors and improved safety features. These developments have made magnetic drills more versatile and reliable, expanding their use across various sectors.

Reza notes that recent innovations have also focused on reducing the weight of these drills without compromising their power, making them easier to handle and transport. This has opened up new possibilities for their application in diverse environments.

Choosing the Right Magnetic Drill

Selecting the right magnetic drill for a specific task can be overwhelming given the variety available on the market. Reza suggests considering several factors when making a choice:

- Material Thickness: Ensure the drill's power is suitable for the thickness of the material.

- Drilling Position: Consider if you will be drilling vertically, horizontally, or overhead.

- Portability: Assess the ease of transporting the drill to various job sites.

By taking these aspects into account, users can select a tool that meets their specific needs while ensuring efficiency and safety.

The Future of Magnetic Drills

Looking ahead, Reza is optimistic about the future of magnetic drill technology. He believes that continued research and development will lead to even more refined tools, enhancing their precision and functionality. The integration of smart technology, such as IoT connectivity, could revolutionize how these drills are operated and maintained.

Reza's expertise and passion for engineering continue to drive innovation in this field, inspiring a new generation of engineers. His work not only highlights the current capabilities of magnetic drills but also paves the way for future advancements that could redefine industry standards.