Mastering Metal Beveling: Expert Tips from Cologne

Understanding the Basics of Metal Beveling

Metal beveling is a crucial process in metalworking, involving the creation of a sloped edge on a metal piece. This technique is essential for enhancing the strength and durability of welds and improving the overall aesthetics of the finished product. Mastering metal beveling can lead to more precise and efficient projects, whether you're working on large industrial structures or intricate metal art.

Understanding the different types of bevels is the first step in mastering this skill. Bevels can vary in angle and depth, depending on the project's requirements. Common types include V-bevels, J-bevels, and U-bevels, each offering unique benefits and applications. Selecting the appropriate bevel type is crucial for achieving the desired final result.

Choosing the Right Tools

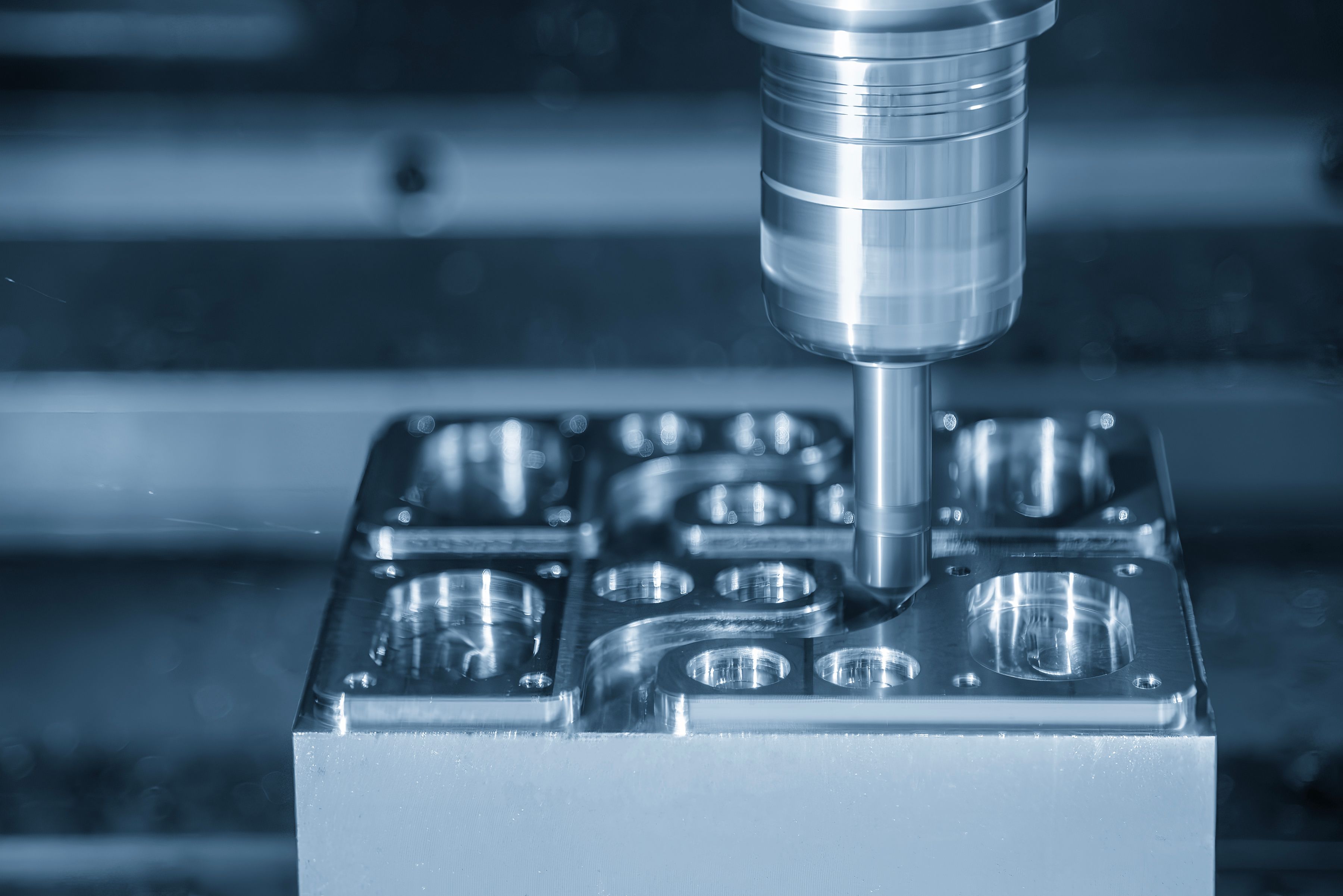

The success of a beveling project heavily relies on selecting the right tools. Various tools are available, ranging from handheld grinders to sophisticated CNC machines. Handheld grinders are ideal for small-scale projects, offering flexibility and control. On the other hand, CNC machines provide precision and consistency for larger, more complex jobs.

When choosing beveling tools, consider factors such as material type, project scale, and desired finish. Investing in high-quality equipment can save time and reduce errors. Additionally, regular maintenance of these tools ensures they remain in optimal condition, leading to smoother operations and prolonged lifespan.

Techniques for Precision and Efficiency

Developing efficient techniques is vital for producing high-quality bevels. One effective method is to start with a rough cut using a grinder, followed by fine-tuning with a file or deburring tool. This two-step process enhances accuracy and minimizes imperfections.

Additionally, maintaining a consistent angle throughout the beveling process is critical. Using angle guides or jigs can help achieve uniformity, leading to better-fitting joints and stronger welds. Practicing these techniques regularly can significantly improve your beveling skills over time.

Safety Measures in Metal Beveling

Safety should always be a top priority when working with metal beveling tools. Proper protective gear, such as gloves, goggles, and ear protection, is essential to prevent injuries. Ensuring that your workspace is well-ventilated and free from obstructions can also contribute to a safer work environment.

Regularly inspecting your tools for wear and damage is another crucial safety measure. Damaged equipment can lead to accidents and compromise the quality of your work. By adhering to safety protocols, you can ensure a secure and productive beveling process.

Learning from the Experts in Cologne

Cologne has long been recognized as a hub for metalworking expertise. Attending workshops and seminars in this city provides an excellent opportunity to learn from experienced professionals. These events often cover advanced techniques and innovative technologies that can enhance your beveling skills.

Networking with fellow metalworkers in Cologne can also be beneficial. Sharing experiences and tips can lead to new insights and improved practices. Engaging with this vibrant community can inspire creativity and foster continuous learning in the field of metal beveling.