Innovative Welding Techniques for 2024

RR

Revolutionizing the Welding Industry

As we step into 2024, the welding industry is witnessing a profound transformation driven by innovative technologies and techniques. Welding, a critical process in manufacturing and construction, is benefiting from advancements that enhance precision, efficiency, and sustainability. This year promises to bring new methodologies that will redefine what is possible in welding.

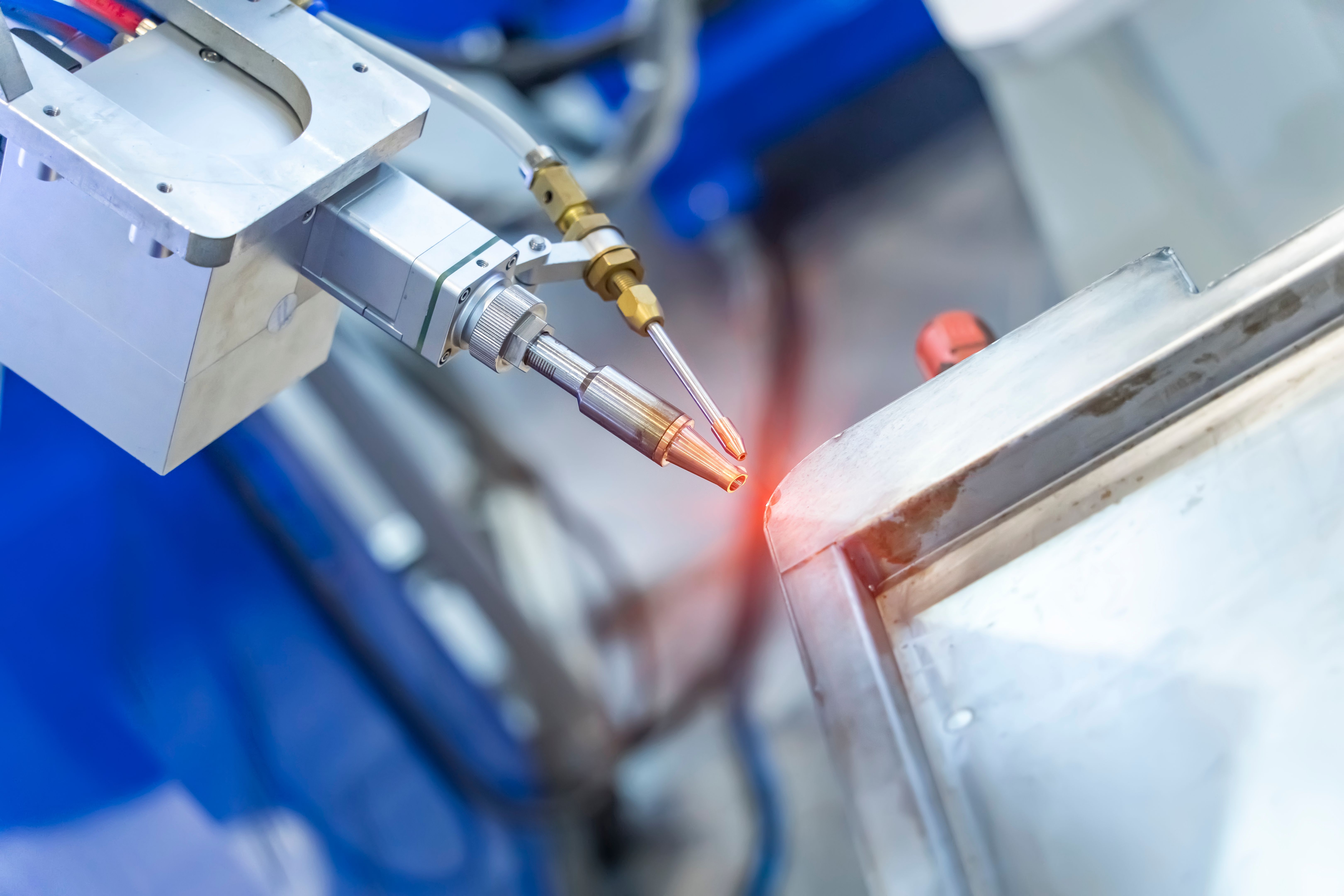

Laser Welding: The Next Frontier

Laser welding continues to gain traction as a preferred technique due to its precision and speed. This method uses a concentrated laser beam to melt materials, resulting in minimal distortion and cleaner welds. The ability to automate laser welding further enhances its appeal, reducing human error and increasing consistency. As industries demand tighter tolerances and faster production rates, laser welding is set to become indispensable.

Moreover, laser welding's ability to join dissimilar materials opens new avenues in product design and manufacturing. This flexibility allows for innovative uses in the automotive and aerospace sectors, where weight reduction and strength are critical.

Advancements in Robotic Welding

Robotic welding is not a new concept, but the sophistication of these systems in 2024 is remarkable. Modern robotic welders are equipped with artificial intelligence and machine learning capabilities, enabling them to adapt to complex tasks with minimal human intervention. These systems can optimize welding parameters in real-time, ensuring the best possible outcome for each joint.

The integration of vision systems allows robots to identify and correct deviations during the welding process. This not only improves quality but also reduces waste, making robotic welding an environmentally friendly option.

Hybrid Welding Techniques

Hybrid welding techniques, which combine different welding methods, are gaining popularity due to their ability to leverage the strengths of each process. For instance, combining laser welding with gas metal arc welding (GMAW) results in a technique that offers both speed and deep penetration. Such combinations are particularly beneficial in industries like shipbuilding and heavy machinery.

Hybrid techniques also provide greater flexibility in adjusting to varying material thicknesses and joint configurations, making them versatile for a wide range of applications.

Sustainable Welding Practices

With an increasing focus on sustainability, the welding industry is exploring ways to reduce its environmental impact. Techniques that minimize waste and energy consumption are becoming more prevalent. For example, cold metal transfer (CMT) is a technique that reduces heat input, resulting in less energy consumption and lower emissions.

Additionally, the use of eco-friendly consumables and materials that produce fewer harmful by-products during welding is on the rise. These practices not only benefit the environment but also lead to cost savings for businesses by reducing material waste and energy bills.

The Future of Welding Education

As welding techniques become more advanced, there is a growing need for skilled professionals who are well-versed in these innovations. Educational institutions are adapting their curricula to include new technologies and methods. Virtual reality (VR) training tools are becoming popular, providing students with realistic simulations for hands-on practice without the risks associated with live welding.

Additionally, online platforms offering courses on advanced welding techniques are making it easier for professionals to upskill and stay current with industry trends. This accessibility ensures that the workforce is prepared to meet the demands of modern manufacturing processes.

Conclusion

The welding industry is on the cusp of a technological revolution that promises to enhance efficiency, precision, and sustainability. As we embrace these innovations in 2024, businesses and professionals alike must adapt to remain competitive. By investing in advanced techniques and education, the industry can look forward to a future where welding continues to play a vital role in global manufacturing and construction.