Exploring the Benefits of Dry Cutting Tools

Understanding Dry Cutting Tools

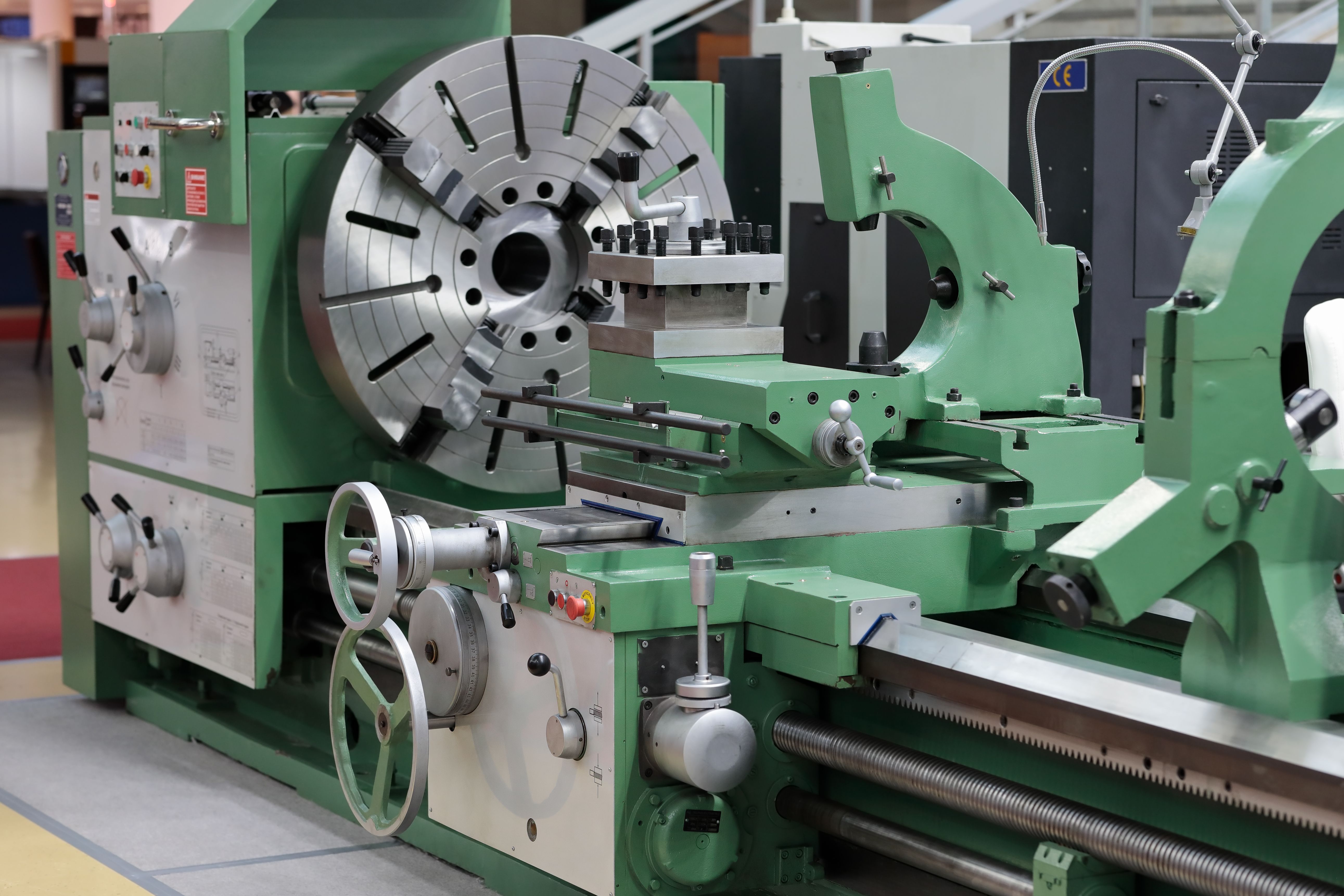

In the world of machining, the choice of tools can significantly impact productivity, cost efficiency, and the quality of the finished product. Among the various options available, dry cutting tools have been gaining popularity for their unique benefits. But what exactly are dry cutting tools? Simply put, they are tools that operate without the use of coolant or lubrication, making them an environmentally friendly and cost-effective choice.

The primary advantage of dry cutting tools is their ability to reduce or completely eliminate the need for cutting fluids. This not only helps in reducing costs associated with purchasing and disposing of these fluids but also alleviates health and safety concerns related to their handling. Moreover, manufacturers are increasingly adopting dry cutting practices to align with sustainable manufacturing goals.

Enhanced Tool Life and Performance

One of the most compelling benefits of dry cutting tools is their enhanced tool life. When designed and applied correctly, these tools can withstand high temperatures generated during cutting operations without compromising their integrity. This leads to longer tool life and reduced downtime for tool changes, ultimately boosting productivity.

Heat management is a critical factor in machining, particularly in high-speed operations. Dry cutting tools are engineered to handle heat more effectively, often incorporating advanced materials like ceramics or coatings that enhance thermal resistance. This capability not only extends tool life but also maintains consistent performance throughout its use.

Surface Finish and Precision

Contrary to some misconceptions, dry cutting can achieve excellent surface finishes and precision. The absence of coolant minimizes the risk of thermal shock and distortion, which can affect dimensional accuracy. As a result, components produced using dry cutting techniques often exhibit superior surface quality and tighter tolerances.

Furthermore, advances in tool design and material technology have empowered dry cutting tools to perform on par with their lubricated counterparts. The use of advanced geometries and coatings allows these tools to cut cleaner and more efficiently, ensuring that manufacturers do not compromise on quality when opting for dry cutting solutions.

Cost Savings and Environmental Impact

The economic advantages of dry cutting tools extend beyond tool longevity. By eliminating the need for coolants, manufacturers can achieve significant cost savings related to purchasing, storing, and disposing of these materials. Additionally, maintenance costs associated with coolant systems are reduced, further enhancing the cost-effectiveness of dry cutting.

From an environmental perspective, dry cutting is a greener alternative that aligns with the growing emphasis on sustainability. It reduces the environmental footprint by minimizing waste and pollution associated with coolant disposal. Moreover, adopting dry cutting practices contributes to workplace safety by reducing exposure to harmful chemicals, creating a healthier work environment.

Applications and Industry Adoption

Dry cutting tools have found applications across various industries, including automotive, aerospace, and electronics manufacturing. Their ability to deliver high performance without the need for coolants makes them particularly suitable for operations involving high-speed machining and materials that are sensitive to thermal variations.

As industries continue to seek ways to enhance efficiency while adhering to environmental regulations, the adoption of dry cutting tools is expected to grow. Manufacturers are investing in research and development to further optimize these tools, ensuring they meet the evolving demands of modern machining processes.

Conclusion: Embracing the Future of Machining

Dry cutting tools represent a paradigm shift in machining practices, offering a myriad of benefits from cost savings to environmental sustainability. As technology advances and more industries recognize the potential of these tools, their adoption is likely to become even more widespread.

For businesses looking to stay competitive while embracing sustainable practices, investing in dry cutting technology could be a strategic move. By doing so, they not only enhance operational efficiency but also contribute positively to environmental conservation efforts.