Expert Insights: Reza Mamaghani Rad on Magnet Drills

wwww.magnetdrill.comUnderstanding the Basics of Magnet Drills

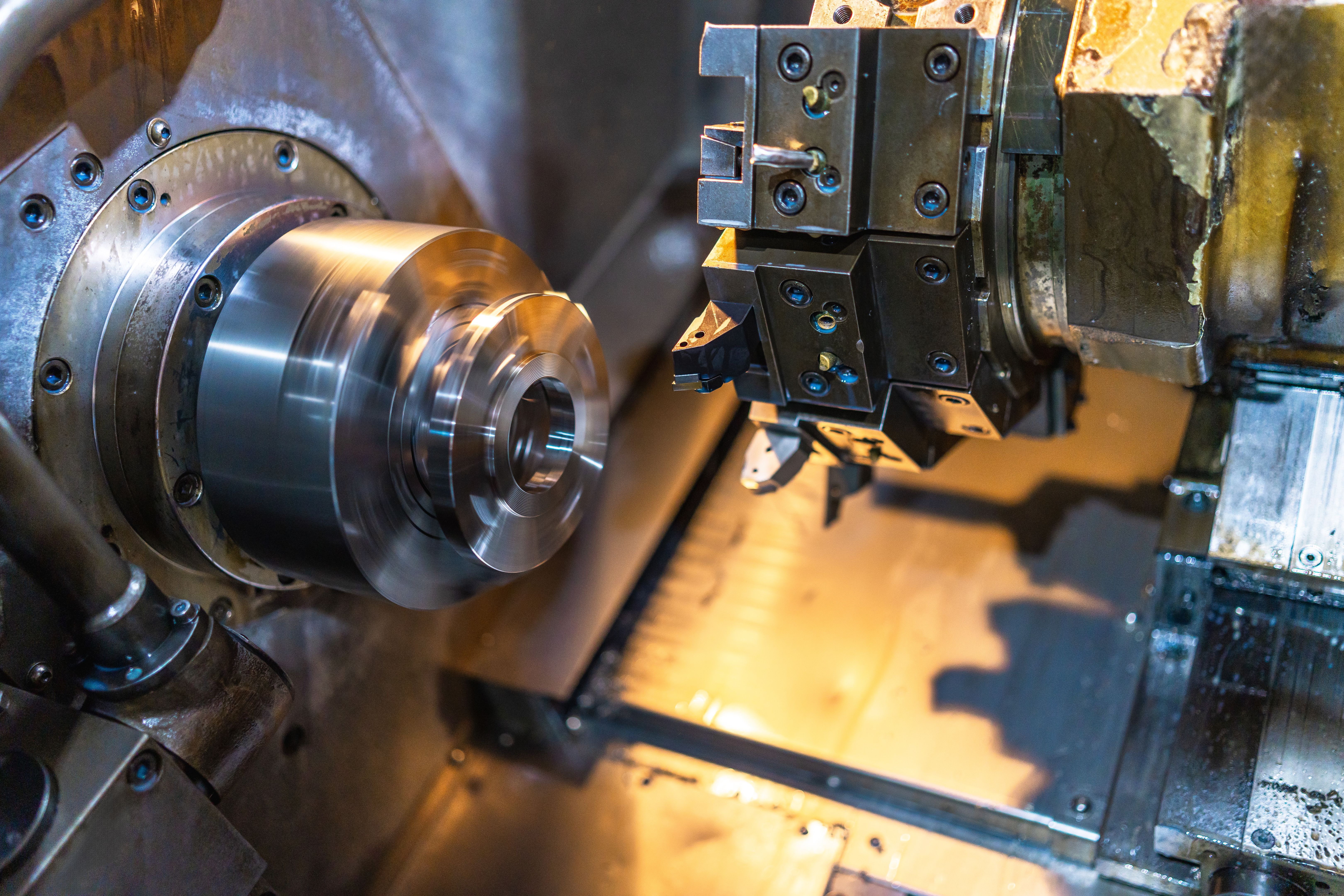

Magnet drills, often regarded as one of the most versatile tools in industrial settings, are essential for tasks that demand precision and power. These devices are equipped with a magnetic base that securely attaches to metal surfaces, ensuring stability during operation. This feature makes them invaluable for tasks such as drilling holes in steel beams and other heavy-duty applications.

According to Reza Mamaghani Rad, a renowned expert in the field of industrial tools, magnet drills are particularly advantageous in construction and manufacturing environments. Their portability and ease of use make them an ideal choice for professionals who require mobility without compromising on performance. Reza emphasizes that understanding the various components and functionalities of these drills is crucial for maximizing their efficiency.

Key Features to Consider

When choosing a magnet drill, there are several important features to consider. Reza highlights the following aspects:

- Motor Power: The motor's power determines the drill's efficiency and the types of materials it can handle. A more powerful motor allows for drilling through thicker and harder materials.

- Magnetic Strength: The strength of the magnetic base is crucial for stability. A stronger magnet ensures that the drill remains firmly attached to the surface, preventing any slips or mishaps.

- Drill Speed: Adjustable speeds allow for greater control, enabling users to adapt to different materials and project requirements.

The Importance of Safety

Safety is a paramount concern when operating magnet drills. Reza Mamaghani Rad stresses the importance of adhering to safety guidelines to prevent accidents and injuries. Users should always wear appropriate protective gear and ensure that the drill is in good working condition before use.

Regular maintenance checks are essential to keep magnet drills functioning optimally. This includes inspecting the magnetic base for any wear or damage and ensuring that all moving parts are lubricated and free from obstructions.

Applications and Versatility

Magnet drills are widely used across various industries due to their versatility. From construction sites to shipyards, these tools prove invaluable in situations where traditional drilling methods fall short. They are particularly useful for overhead drilling and operations in confined spaces where maneuverability is limited.

Reza Mamaghani Rad points out that the adaptability of magnet drills makes them suitable for a range of tasks beyond mere drilling. With the right attachments, they can be used for cutting, tapping, and even reaming, expanding their utility across different projects.

Future Trends and Innovations

The world of magnet drills is not static; it is continuously evolving with technological advancements. Reza notes that recent innovations focus on improving battery life and enhancing the magnetic force without increasing the weight of the drill. These developments aim to make magnet drills more efficient and user-friendly, catering to the ever-growing demands of modern industries.

As technology progresses, we can expect even more sophisticated features, such as smart control systems that integrate with digital platforms for enhanced precision and monitoring. This evolution signifies a promising future for magnet drills, making them indispensable tools in various fields.