Choosing the Perfect Hole Cutters for Your Needs

RR

Understanding Hole Cutters

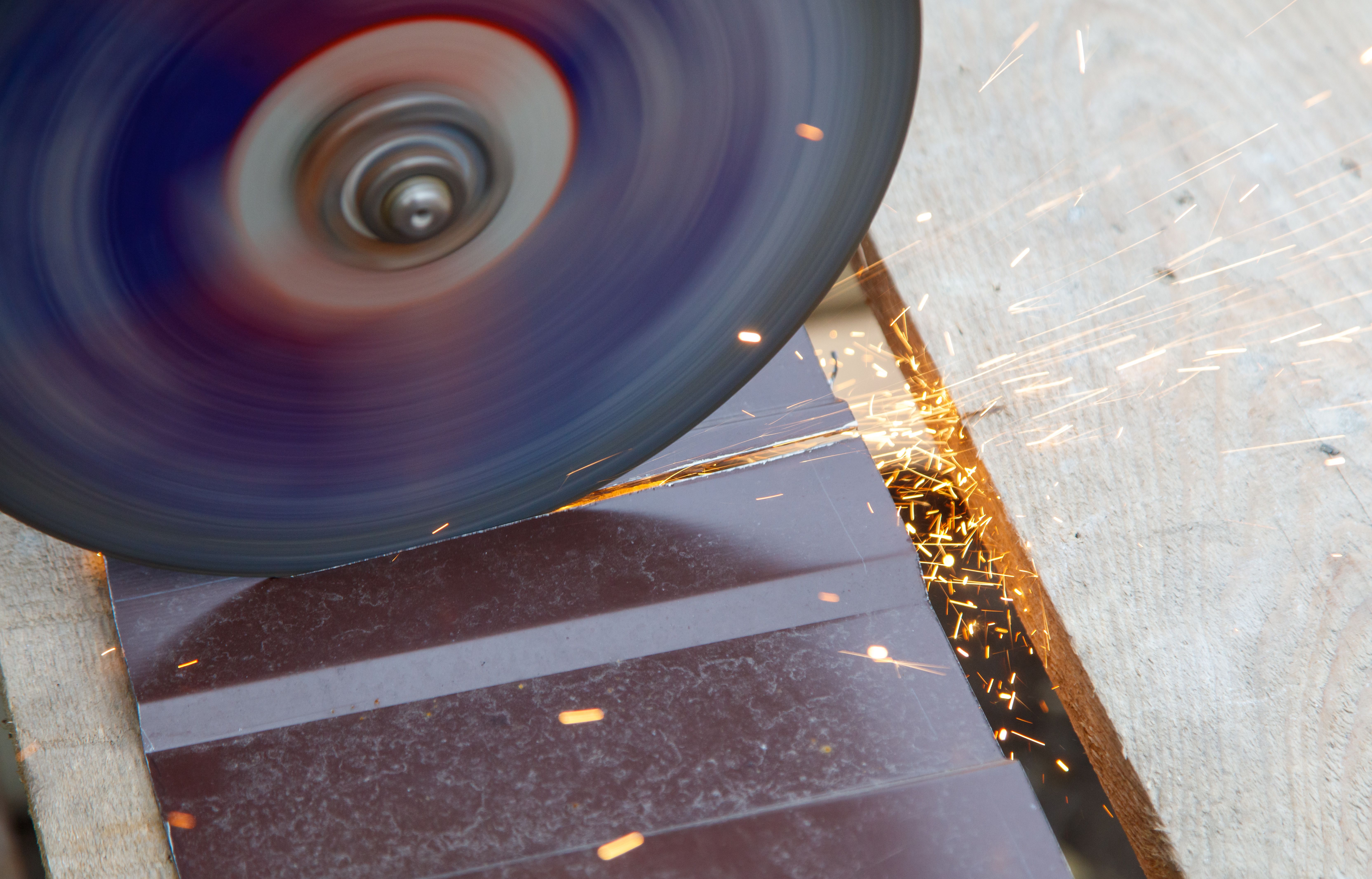

When it comes to drilling precise holes in various materials, choosing the right hole cutter is crucial. Whether you're working with wood, metal, or plastic, the correct tool can make all the difference in the quality and efficiency of your project. But with so many options available, how do you select the perfect one for your needs?

Hole cutters, also known as hole saws, come in a variety of sizes and materials. Each type is designed for specific applications, ensuring you get clean, accurate cuts every time. Understanding the different types of hole cutters and their uses will help you make an informed decision.

Types of Hole Cutters

There are several types of hole cutters, each suited for different materials and purposes:

- Bi-Metal Hole Cutters: These are versatile and can cut through wood, plastic, and thin metals with ease. They are durable and resist wear.

- Carbide-Tipped Hole Cutters: Ideal for cutting through harder materials such as stainless steel and cast iron. They offer greater longevity and precision.

- Tungsten Carbide Grit Hole Cutters: Best suited for abrasive materials like tiles and ceramics. They provide clean cuts without chipping.

Factors to Consider When Choosing a Hole Cutter

Several factors should be considered when selecting the right hole cutter for your project:

- Material: Determine the type of material you will be cutting. This will guide your choice between bi-metal, carbide-tipped, or tungsten carbide grit hole cutters.

- Size: Consider the diameter of the holes you need to cut. Hole cutters come in various sizes, so ensure you select one that meets your requirements.

- Depth of Cut: Look for a hole cutter that can handle the thickness of the material you are working with to ensure a clean cut.

Additional Tips for Using Hole Cutters

Once you've chosen the right hole cutter, it's important to use it properly to achieve the best results:

- Secure the Material: Before drilling, ensure that your material is clamped or secured to prevent movement during the cutting process.

- Use Lubrication: For metal cutting, applying lubrication helps reduce friction and heat, prolonging the life of your tool.

- Avoid Overheating: Take breaks between cuts to prevent overheating both the tool and the material.

Maintaining Your Hole Cutters

To extend the life of your hole cutters, regular maintenance is key. After each use, clean the cutter thoroughly to remove debris. Sharpening or replacing dull teeth can also improve performance. Proper storage in a dry environment will prevent rust and corrosion.

Selecting the perfect hole cutter requires a bit of research and consideration, but by understanding your specific needs and the options available, you can make an informed choice. With the right tool in hand, you'll be well on your way to achieving precise and professional results in all your drilling projects.

Remember, investing time in choosing the right hole cutter will not only enhance your craftsmanship but also save you time and effort in the long run. Happy drilling!